310 stainless steel pipe

The 310 stainless steel pipe offers several advantages, notably its exceptional high-temperature strength and corrosion resistance, particularly in demanding environments. Widely used in industries such as furnace manufacturing, heat treatment, and chemical processing, it serves as a reliable choice for components subjected to extreme temperatures and corrosive substances. Its chromium and nickel-rich composition ensures robust resistance to oxidation and sulfidation, guaranteeing longevity in harsh conditions. Overall, the 310 stainless steel pipe provides enduring performance and durability in environments where high-temperature strength and corrosion resistance are crucial.

904 stainless steel pipe

The 904 stainless steel pipe boasts several advantages, including exceptional corrosion resistance and high strength in aggressive environments. Widely utilized in marine engineering, chemical processing, and oil and gas industries, it stands as a reliable choice for components exposed to corrosive substances and harsh conditions. Its high chromium, nickel, and molybdenum content ensure robust resistance to corrosion, making it suitable for critical applications. Overall, the 904 stainless steel pipe offers enduring performance and durability in environments where both corrosion resistance and strength are paramount.

1.4529 stainless steel pipe

The 1.4529 stainless steel pipe presents several advantages, including exceptional corrosion resistance and high strength in aggressive environments. Widely utilized in chemical processing, oil and gas, and marine engineering industries, it serves as a reliable choice for components exposed to corrosive substances and harsh conditions. Its high chromium, nickel, and molybdenum content ensure robust resistance to corrosion, making it suitable for critical applications. Overall, the 1.4529 stainless steel pipe offers enduring performance and durability in corrosive environments where both corrosion resistance and strength are paramount.

434 stainless steel pipe

The 434 stainless steel pipe offers several advantages, including moderate corrosion resistance and high strength suitable for various applications. Widely utilized in automotive manufacturing, construction, and industrial equipment industries, it provides reliability in environments with moderate corrosive substances and mechanical stress. Its composition, rich in chromium and molybdenum, strikes a balance between corrosion resistance and strength, making it versatile for diverse applications. Overall, the 434 stainless steel pipe ensures reliable performance and durability where moderate corrosion resistance and high strength are essential.

440A stainless steel pipe

The advantages of 440A stainless steel pipe lie in its moderate corrosion resistance and excellent edge retention properties. Widely used in cutlery manufacturing, surgical instruments, and kitchen appliances, it excels in applications where components must withstand moderate corrosive environments while maintaining sharp edges. Its composition, featuring carbon and chromium, ensures good hardness and wear resistance, making it ideal for cutting tools and applications requiring prolonged sharpness. Overall, 440A stainless steel pipe offers reliability and durability in environments where moderate corrosion resistance and superior edge retention are essential.

440C stainless steel pipe

The 440C stainless steel pipe offers several advantages, including exceptional hardness, wear resistance, and corrosion resistance, making it suitable for demanding applications. Widely used in aerospace, tool manufacturing, and cutlery production, it excels in components subjected to heavy loads, abrasion, and corrosive environments. Its composition, featuring carbon and chromium, ensures outstanding hardness and wear resistance, ideal for critical components enduring extreme conditions. Overall, the 440C stainless steel pipe provides reliability and durability in applications where high performance and corrosion resistance are crucial.

seamless stainless steel pipe

Seamless stainless steel pipes find application across diverse industries due to their exceptional corrosion resistance, high strength, and reliability. They are extensively used in the oil and gas sector for transporting corrosive fluids and gases, in chemical processing plants for handling aggressive chemicals, and in the food and beverage industry for maintaining hygiene standards. Additionally, they serve in structural applications in construction, in automotive and aerospace sectors for critical components, and in power generation plants for conveying high-pressure steam and gases. Their versatility and durability make them indispensable in numerous industrial and commercial applications.

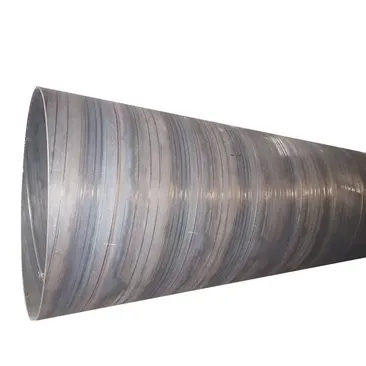

welded stainless steel pipe

The advantages of welded stainless steel pipes include cost-effectiveness, versatility, and ease of customization. Welded pipes are produced by welding steel strips or plates together, allowing for efficient mass production and lower manufacturing costs compared to seamless pipes. They can be fabricated in various shapes and sizes to suit specific application requirements, offering flexibility in design. Welded stainless steel pipes also exhibit good mechanical properties and can withstand high temperatures and pressures, making them suitable for a wide range of industrial and structural applications. Additionally, welded pipes are readily available in large quantities, providing a reliable and accessible solution for various piping needs.

A106 GRB Carbon steel pipe

The A106 carbon steel pipe offers several key advantages, including excellent strength and durability, making it suitable for high-pressure and high-temperature applications. It has outstanding weldability and machinability, facilitating easy fabrication and installation in complex piping systems. Its ability to withstand harsh conditions and maintain structural integrity under extreme temperatures and pressures makes it ideal for critical applications in oil and gas refineries, power plants, and petrochemical plants. Overall, the A106 carbon steel pipe combines strength, reliability, and versatility, ensuring optimal performance in demanding industrial environments.

stainless steel square pipe

Stainless steel square tubes offer numerous advantages, including exceptional strength and durability, which make them suitable for structural applications. They provide excellent corrosion resistance, ensuring longevity even in harsh environments. Their uniform shape and smooth surface enhance aesthetic appeal and facilitate easy cleaning, making them ideal for architectural and sanitary applications. Additionally, these tubes are versatile and easy to fabricate, allowing for customized designs and installations. Their high tensile strength, combined with resistance to extreme temperatures, makes stainless steel square tubes a reliable and cost-effective choice for a wide range of industrial and commercial uses.