6082 Aluminum coil

It also has moderate strength and can maintain good operability after annealing.

It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

CLASSIFICATION :

KEYWORDS :

6082 Aluminum coil

MOQ :

2 TONS

CUSTOMIZED:

Customized Logo , Customized Packaging , Product Customization

PRODUCT DETAILS

About the aluminum

6082 is a heat-treatable alloy with good formability, weldability, machinability and corrosion resistance. It also has moderate strength and can maintain good operability after annealing. It is mainly used in mechanical structure, including bars, plates, pipes and profiles. This alloy has similar but not identical mechanical properties to alloy 6061, and its -T6 state has higher mechanical properties. Alloy 6082 is a common alloy product in Europe and has high application in the United States for processing raw materials, seamless aluminum tubes, structural profiles and custom profiles. 6082 alloy usually has good machining properties and good anodic reactivity. The most common anodic reaction methods include impurity removal and staining, coating, etc.

Alloy 6082 combines excellent solderability, brazing, corrosion resistance, formability and machinability. Alloy 6082's -0 and T4 states are suitable for bending and forming occasions, its -T5 and -T6 states are suitable for good machinability requirements, some special processing needs to use chip separator or other special processes to help separate chips; 6082 alloy usually has good machining properties and good anodic reactivity.

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

PRODUCT

| Thickness | 0.1-400mm,etc | Length: | 100-12000mm,or as required |

| Width | 20-3000mm,etc | Standard: | ASTM,AISI,JIS,GB, DIN,EN |

| Certification: | ISO, SGS,BV | ||

| Surface finish | mill,bright,polished,hair line,brush,sand Blast,checkered,embossed,etching,etc | ||

| Grade | 1000 Series: 1050 1060 1070 1100 1200 1235 etc. | ||

| 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. | |||

| 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. | |||

| 6000 Series: 6061 6063 6082 6A02 etc. | |||

| 7000 Series: 7050 7475 7075 etc. | |||

| Temper | H12,H14,H16,H18,H20,H22,H24,H26,H28,H32,H36,H38,HO,H111,H112,H114,H116,H118,H321. | ||

| Payment Terms | T/T, L/C at sight,West Union | Loading port | any port in China |

| Packing | standard export packing (inside:water proof paper,outside:steel covered with strips and pallets) | ||

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) | ||

| 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) | |||

| 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) | |||

Jiangsu Hengdali Steel Industry Co., Ltd. is a modern enterprise integrating production, processing and trade, and is a leading iron and steel enterprise group in China.

The main products of the company: seamless steel pipe, steel plate, round rod, galvanized pipe, galvanized sheet, copper plate, copper pipe, aluminum plate, aluminum tube, PPGI,PPGL, stainless steel plate, stainless steel tube, stainless steel belt, stainless steel products, etc.

Packing and shipping

Our products rely on high-quality product quality, good reputation, and innovative marketing concepts, selling well overseas, such as the United States, Europe, the Middle East, Southeast Asia, Japan, South Korea and other more than 80 countries around the world, with close and good trade partnerships.

Application field

The company has established strategic partnership with well-known iron and steel enterprises to achieve effective integration of production, supply and marketing resources and further improve product quality. Through years of unremitting efforts and hard work, the company builds a reputation system with excellent quality, and trusts merchants with comprehensive and meticulous service.

Customer visit

Application Areas

We guarantee you a product at a competitive price and we will be at your service to meet all your specifications and needs.

Integrating production, processing and trade

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, etc.

CERTIFICATE

FAQ

Q2:What product information do I need to provide?

Q3:It's my first time to import steel products, can you help me with it?

A:Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:What about product prices information?

A:Prices various according to periodic price changes of raw materials.

Q5:What ports of shipment are there?

Q6:What is your terms of payment ?

RELATED PRODUCTS

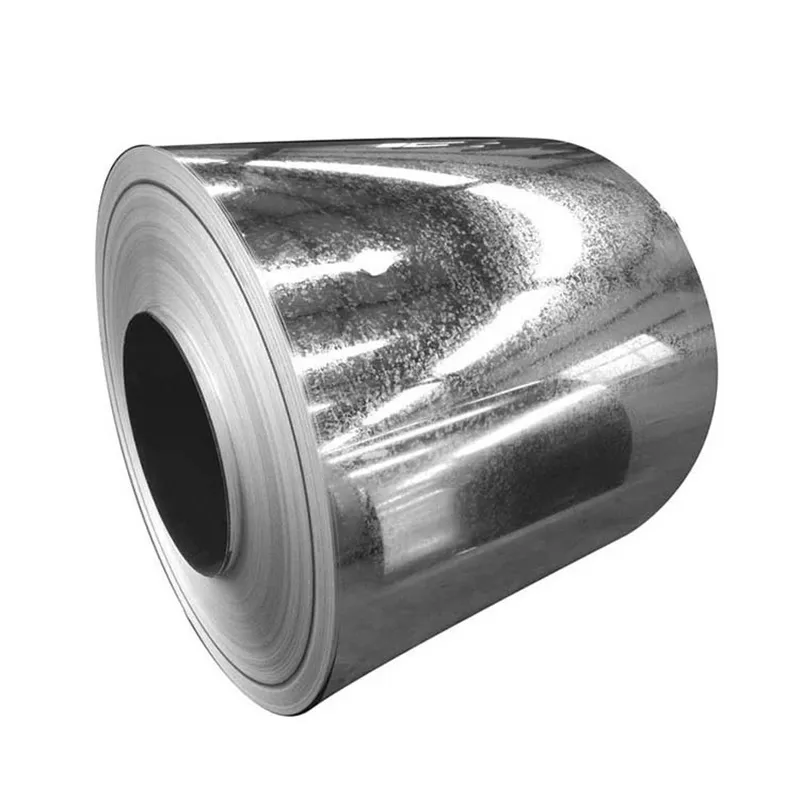

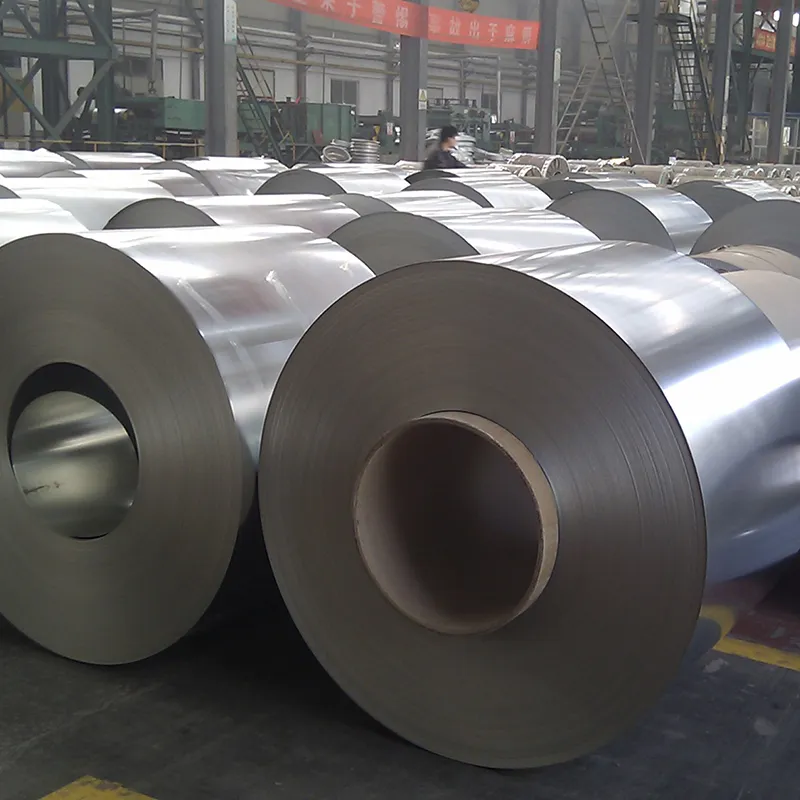

Galvanized steel coils offer several key advantages, including excellent corrosion resistance due to their protective zinc coating, which extends their lifespan and reduces maintenance costs. They provide superior durability and strength, making them suitable for demanding applications in construction and manufacturing. These coils are also cost-effective, offering a good balance between performance and price. Their versatility allows for easy fabrication and welding, accommodating various design requirements. Additionally, galvanized steel coils are aesthetically pleasing with a clean, uniform appearance, and they are environmentally friendly as they can be recycled.

View DetailsStainless steel coils are imported and domestic products, divided into hot-rolled and cold-rolled. According to the needs of different users, we can also order a variety of special-shaped steel materials.In order to ensure that the yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery.

View DetailsThe advantages of 440C stainless steel coils are rooted in their exceptional hardness, corrosion resistance, and wear resistance properties. Widely employed in the production of high-performance knives, bearings, and surgical instruments, these coils offer outstanding edge retention and durability. Their high carbon content enhances hardness and wear resistance, ensuring precision cutting and long-term performance in demanding applications. Additionally, their corrosion resistance guarantees reliability in harsh environments, making them a preferred choice for critical components across diverse industrial sectors.

View DetailsThe advantages of 440A stainless steel coils lie in their exceptional hardness, corrosion resistance, and edge retention properties. Widely utilized in the production of knives, cutting tools, and surgical instruments, these coils offer outstanding sharpness and durability. Their ability to maintain sharp edges even under rigorous use makes them ideal for precision cutting tasks. Furthermore, their corrosion resistance ensures long-term reliability in diverse environments, enhancing their suitability for a wide range of industrial and commercial applications.

View DetailsGET A FREE QUOTE