7075-T6 Aluminum foil

7075T6 aluminumalloy is precision machined aluminum in the United States, one of the most commercially available alloys.

The main alloyingelement of 7075 series is zinc, which has strong strength, good mechanical properties and anode reaction.

CLASSIFICATION :

KEYWORDS :

7075-T6 Aluminum foil

MOQ :

1 ton

CUSTOMIZED:

Customized Logo , Customized Packaging , Product Customization

PRODUCT DETAILS

About the aluminum

7075-T6 aluminum alloy hardness is 150HB, belongs to the high hardness aluminum alloy. 7075T6 aluminum alloy is precision machined aluminum in the United States, one of the most commercially available alloys. The main alloying element of 7075 series is zinc, which has strong strength, good mechanical properties and anode reaction. 7075 aluminum heat treatment is because zinc is the main alloying element in 7075, adding magnesium to the alloy containing 3%-7.5% zinc can form a significant strengthening effect of MgZn2, so that the heat treatment effect of the alloy is far better than the al-zinc binary alloy; With the increase of zinc and magnesium content, the tensile strength of the alloy will be further improved, but its resistance to stress corrosion and spalling corrosion will decrease.

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃,

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

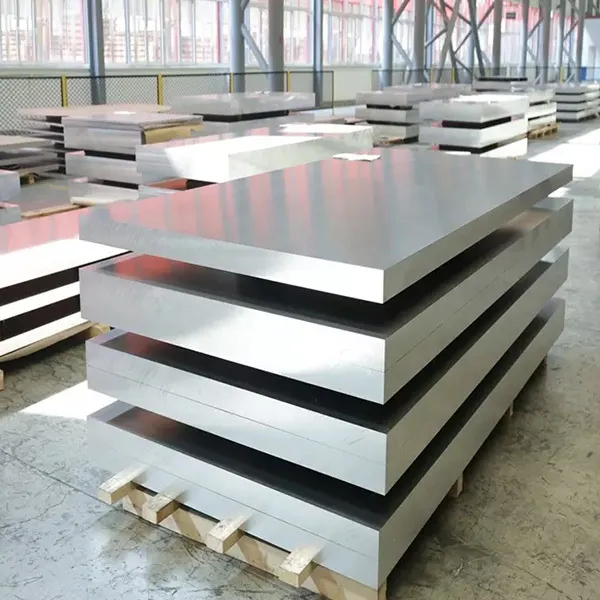

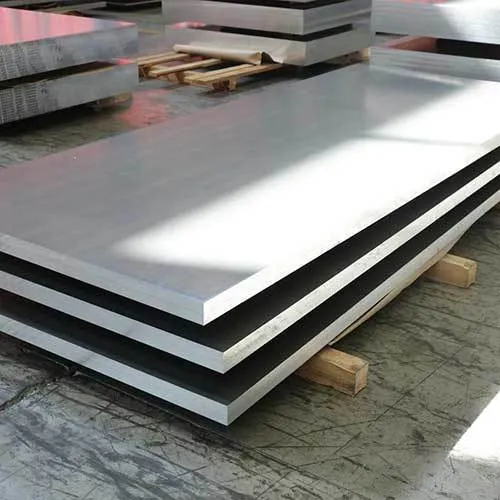

PRODUCT

| Standard | ASTM GB JIS AISI,EN |

| Thickness | 0.006mm(6micron) - 0.2mm (200micron) |

| Width | 120- 1500 mm (tolerance:± 1.0mm) |

| Temper | O,F, H12, 114,H18,H22, H24,H26,H32, etc |

| Application | Aluminum foil is widely used in food, beverage, cigarette, medicine, photographic plate, household articles, etc. It is usually used as its packaging material, electrolytic capacitor materials, insulation materials for buildings, vehicles, ships and houses. |

| Price Term | Ex-work, FOB, CFR, CIF, etc |

| Delivery Time | 20-30 days. Standard size is in stock,prompt delivery or as order's quantity. |

| Package | Export standard package, Carton box or wooden case, or waterproof paper, or as customer's request. |

| The inner size of container is below: | |

| 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high)about 24-26CBM | |

| 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM |

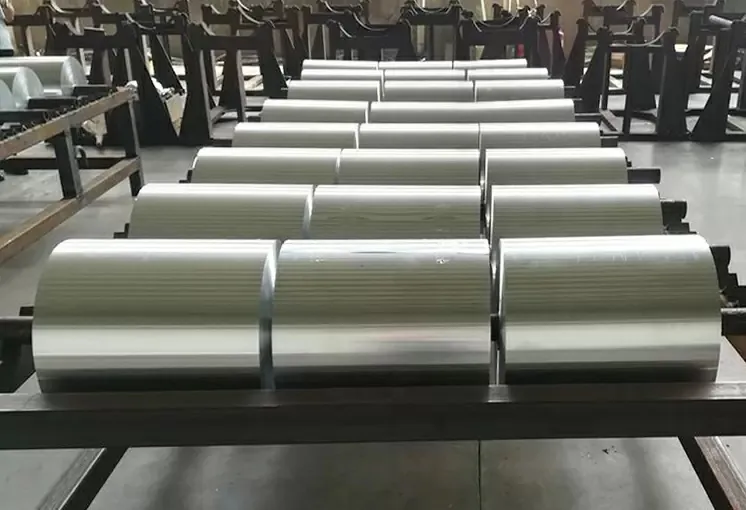

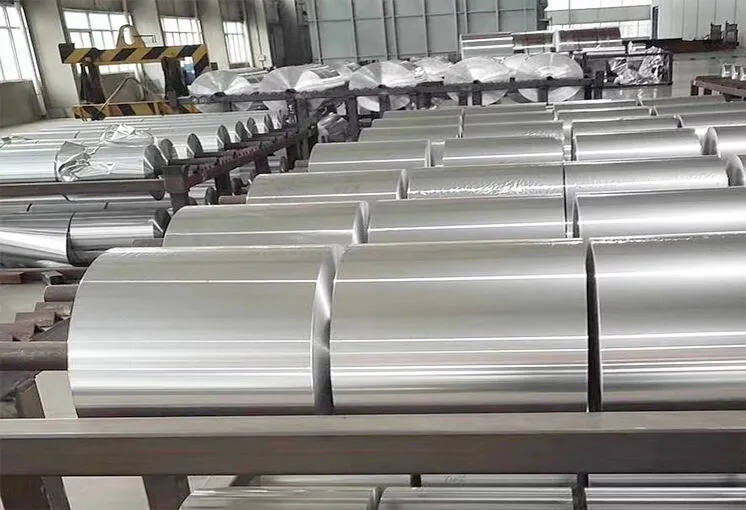

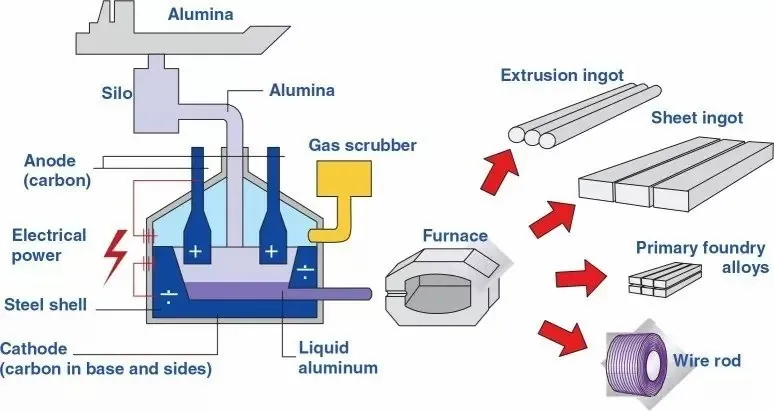

Aluminum Production Process

Jiangsu Hengdali Steel Industry Co., Ltd. is a modern enterprise integrating production, processing and trade, and is a leading iron and steel enterprise group in China.

The main products of the company: seamless steel pipe, steel plate, round rod, galvanized pipe, galvanized sheet, copper plate, copper pipe, aluminum plate, aluminum tube, PPGI,PPGL, stainless steel plate, stainless steel tube, stainless steel belt, stainless steel products, etc.

Packing and shipping

Our products rely on high-quality product quality, good reputation, and innovative marketing concepts, selling well overseas, such as the United States, Europe, the Middle East, Southeast Asia, Japan, South Korea and other more than 80 countries around the world, with close and good trade partnerships.

Application field

The company has established strategic partnership with well-known iron and steel enterprises to achieve effective integration of production, supply and marketing resources and further improve product quality. Through years of unremitting efforts and hard work, the company builds a reputation system with excellent quality, and trusts merchants with comprehensive and meticulous service.

Customer visit

Application Areas

We guarantee you a product at a competitive price and we will be at your service to meet all your specifications and needs.

Integrating production, processing and trade

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, etc.

CERTIFICATE

FAQ

Q2:What product information do I need to provide?

Q3:It's my first time to import steel products, can you help me with it?

A:Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:What about product prices information?

A:Prices various according to periodic price changes of raw materials.

Q5:What ports of shipment are there?

Q6:What is your terms of payment ?

RELATED PRODUCTS

7075 aluminumalloy is a cold - treated forging alloy, high strength, far better than mild steel.

7075is one of the strongest alloys commercially available.

Under heat treatment, can achieve very high strength characteristics.

The alloyalso has good mechanical properties and anode reaction.

Aluminumis a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used.

5083 belongsto Al-Mg-Si alloy, which is widely used, especially in the construction industry.

It is the most promising alloy.Good corrosion resistance, good weldability, good cold processing, and has moderate strength.

5083 is magnesium,which has good forming performance, corrosion resistance, weldability and medium strength.

5083 aluminumis one of the most widely used antirust

2024 aluminumplate is a typical duralumin in al-cop-magnesium system with reasonable composition and good comprehensive properties.

The alloyis produced in many countries and is the most widely used duralumin.

The characteristicsof the alloy are: high strength, a certain degree of heat resistance, can be used for working parts below 150℃.

The strength of 2024alloy is higher than that of 7075 alloy at temperatures above 125℃.

7075-T6 aluminum alloyhardness is 150HB, belongs to the high hardness aluminum alloy.

7075T6 aluminum alloyis precision machined aluminum in the United States, one of the most commercially available alloys.

The main alloyingelement of 7075 series is zinc, which has strong strength, good mechanical properties and anode reaction.

7075 aluminumheat treatment is because zinc is the main alloying element in 7075, adding magnesium to the alloy containing 3%-7.5% zinc can form a significant strengthening effect of MgZn2, so that the heat treatment effect of the alloy is far better than the al-zinc binary alloy; With the increase of zinc and magnesium content, the tensile strength of the alloy will be further improved, but its resistance to stress corrosion and spalling corrosion will decrease.

GET A FREE QUOTE