316L stainless steel is commonly used in pulp and paper making equipment, heat exchanger, dyeing equipment, film processing equipment, pipes, materials used for the exterior of buildings in coastal areas, as well as watch chains and case of advanced watches.

201 stainless steel is mainly used for decorative tubes, industrial tubes and some shallow stretched products. Such as: oil waste gas combustion pipeline; Engine exhaust pipe; Boiler shell, heat exchanger and heating furnace components; Silencing parts for diesel engine; Boiler pressure vessel; Chemical transport vehicle; Expansion joint; Spiral welded pipe for gas furnace pipe and dryer, etc.

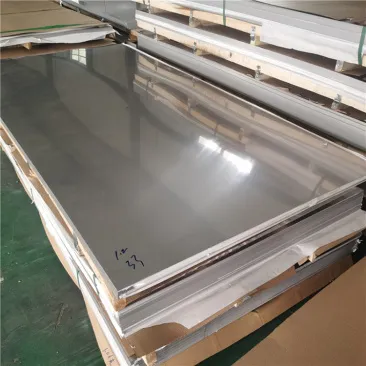

304L stainless steel is mainly used in automobile accessories, hardware tools, tableware, cabinets, medical appliances, office equipment, weaving, handicrafts, petroleum, electronics, chemicals, textile, food, machinery, construction, nuclear power, aerospace, military and other industries.

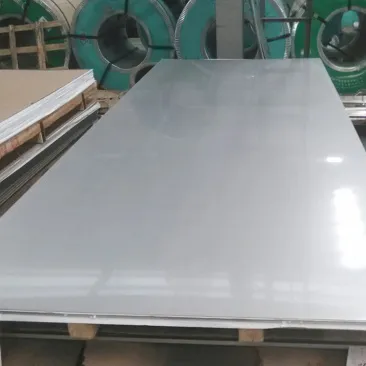

904L stainless steel plate (super austenitic stainless steel) is a high alloyed austenitic stainless steel with very low carbon content. It has good corrosion resistance in dilute sulfuric acid and is specially designed for environments with severe corrosion conditions. It has high chromium content and sufficient nickel content. The addition of copper makes it have strong acid resistance, especially high resistance to chloride interstitial corrosion and stress corrosion cracking. It is not easy to appear corrosion spots and cracks. Its pitting resistance is slightly better than that of other steels. It has good processability and weldability, and can be used for pressure vessels.

2507 stainless steel is used in oil and natural gas industry; Offshore stone skyshatter oil platform (heat exchanger pipe, water treatment and water supply system, fire protection system, water spraying system, water stabilization system; petrochemical equipment; desalination (desalination) equipment (and high-pressure pipe and seawater pipe in the equipment). Mechanical and structural components that require both high strength and high corrosion resistance: fuel (waste) gas purification equipment.

430 stainless steel is used for building decoration, fuel burner parts, household appliances and household appliances. 430F is a steel with free cutting property added to 430 steel, mainly used for automatic lathes, bolts and nuts. 430LX adds Ti or Nb to 430 steel to reduce the content of C, which improves the processability and welding performance. It is mainly used in hot water tanks, hot water supply systems, sanitary appliances, household durable appliances, bicycle flywheels, etc.

310s stainless steel plate is widely used in kiln, high-temperature furnace, boiler, furnace liner high-temperature equipment, such as kiln car, boiler liner, high-temperature furnace, high-temperature furnace tube, combustion machine liner, etc. It can be used for high-temperature equipment. The product is resistant to high temperature and heat. 310s stainless steel plate has good creep strength and can work continuously under high temperature. The working temperature of 310S stainless steel is 1200 ℃, and it can work continuously at 1100 ℃. It is mainly used to manufacture high temperature exhaust pipe, high temperature furnace, high temperature furnace liner, crematory furnace and other steel grades requiring heat resistance, as well as high temperature and high temperature contact parts.

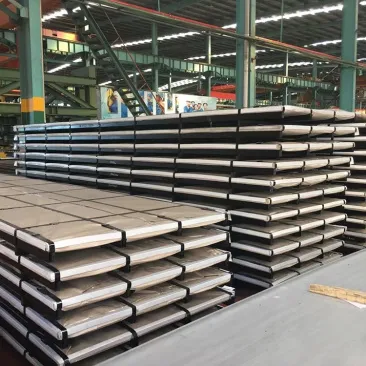

Stainless steel is an alloy of Iron with a minimum of 10.5% Chromium. Chromium produces a thin layer of oxide on the surface of the steel known as the passive layer. This prevents any further corrosion of the surface. Increasing the amount of Chromium gives an increased resistance to corrosion.

A36 is an American standard carbon structural plate, which is subject to ASTM A36/A36M. This standard is applicable to riveting, bolting and welding structures for bridges and buildings, as well as general purpose structural steel quality carbon steel sections, plates and bars.

S355 Carbon steel plate is a carbon steel used in buildings, bridges, ships, vehicles and other structures, which must have a certain strength and require impact performance and welding performance when necessary.