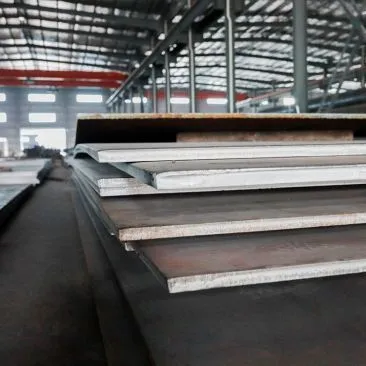

ASTM A283 is a carbon steel plate for general structural use with low to medium tensile strength. The ASTM A283 steel specification covers four structural quality grades of low carbon steel plates for general application, Grade A, B, C, and D.

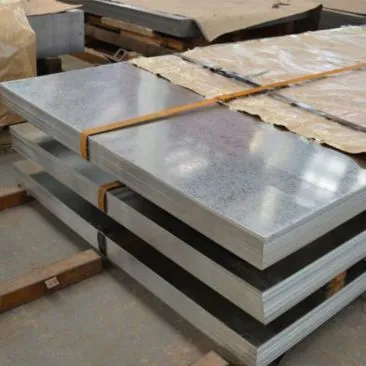

ST12 is German standard (DIN1623), It's ordinary cold rolled steel. In principle, ST12 can only be bent and formed, and no stamping is allowed.

AH36 steel plate is a steel plate with a thickness of no more than 150 mm for the manufacture of ocean going, coastal and inland navigation ships, fishing boats and offshore engineering structures. For steel plates with Z-direction requirements, add Z25 and Z35 to the suffix, which is used as structural steel for high-strength ships and offshore engineering.

NM500 steel plate is a high-strength wear-resistant steel plate with high wear resistance.NM500 wear-resistant steel plate is widely used in engineering machinery, environmental protection machinery, metallurgical machinery, abrasives, bearings and other product parts.

S275JR steel plate is generally used for drilling machines, shovels, electric wheel dumpers, excavators, bulldozers, various cranes, coal mine hydraulic supports and other mechanical equipment and other structural parts used in construction and various projects.

SPCC carbon steel plate is generally used in the production of steel structures, vehicles, ships and bridges, and has good corrosion resistance and atmospheric corrosion resistance.

NM400 wear-resistant carbon steel plate is widely used in mining machinery, coal mining machinery, environmental protection machinery, engineering machinery, etc. It is also commonly used as high-strength structural steel with yield strength ≥ 800MPa.

SA516Gr. 70 is widely used in petroleum, chemical industry, power station, boiler and other industries to make reactors, heat exchangers, separators, spherical tanks, gas tanks, liquefied gas tanks, nuclear reactor pressure shells, boiler drums, liquefied petroleum gas cylinders, high-pressure water pipes of hydropower stations, water turbine shells and other equipment and components.

DC01 Galvanized steel sheet is used for automobiles, sanitary ware, food machinery, pressure vessels, nuclear power, chemical equipment, elevators, rail transit, machinery manufacturing, structural piping, and architectural decoration.

Q195 galvanized sheet is a surface galvanized sheet with yield strength of 195MPa.