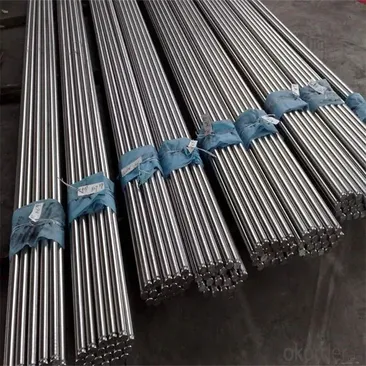

304n stainless steel round bar

The 304N stainless steel round bar offers several advantages, including enhanced strength, improved toughness, and superior corrosion resistance. The addition of nitrogen to its composition increases its tensile strength and durability, making it ideal for high-stress applications. It maintains excellent performance in harsh environments, such as marine and industrial settings, due to its robust corrosion resistance. Additionally, its good weldability and formability allow for versatile fabrication and use in various structural and engineering applications. Overall, the 304N stainless steel round bar provides a reliable and durable solution for demanding applications requiring both strength and resistance to environmental factors.

The 321 stainless steel round bar offers several key advantages, including excellent resistance to intergranular corrosion, superior high-temperature stability, and enhanced weldability. The addition of titanium prevents carbide precipitation during welding, maintaining its strength and corrosion resistance in temperatures up to 900°C (1652°F). This makes it particularly suitable for high-temperature applications such as exhaust manifolds, furnace components, and heat exchangers. Additionally, its robustness and durability ensure reliable performance in demanding environments, such as the aerospace, chemical, and petrochemical industries. Overall, the 321 stainless steel round bar provides a durable and heat-resistant solution for applications requiring long-term stability and corrosion resistance.

The 316 stainless steel round bar boasts several significant advantages, including outstanding corrosion resistance, particularly against chlorides and acidic environments, making it ideal for marine and chemical applications. Its high molybdenum content enhances its resistance to pitting and crevice corrosion. The alloy also offers excellent strength and durability, ensuring reliable performance under harsh conditions. Additionally, it has good weldability and formability, allowing for versatile use in a wide range of industrial applications, from medical devices and food processing equipment to structural components and fasteners. Overall, the 316 stainless steel round bar provides a robust, long-lasting solution for demanding environments requiring superior corrosion resistance.

316h stainless steel round bar

The 316H stainless steel round bar offers several key advantages, notably its superior strength and corrosion resistance at high temperatures. Its elevated carbon content enhances its ability to withstand creep and thermal cycling, making it ideal for applications in high-temperature environments such as heat exchangers, boilers, and furnace components. Additionally, its excellent corrosion resistance ensures durability in corrosive settings, extending its lifespan in harsh industrial conditions. The alloy's versatility, coupled with its reliable performance, makes it a preferred choice for critical applications where both strength and resistance to thermal and chemical degradation are paramount. Overall, the 316H stainless steel round bar provides a robust solution for demanding high-temperature applications.

316ti stainless steel round bar

The 316Ti stainless steel round bar offers several key advantages, including superior corrosion resistance, particularly in high-temperature environments, due to the addition of titanium. This stabilizing element prevents carbide precipitation during welding and extended exposure to elevated temperatures, maintaining the alloy's strength and corrosion resistance. It also exhibits excellent mechanical properties and durability, making it suitable for demanding industrial applications. Furthermore, its enhanced resistance to pitting and crevice corrosion ensures reliable performance in harsh, corrosive environments. Overall, the 316Ti stainless steel round bar provides a robust, long-lasting solution for high-temperature and highly corrosive applications.

The 347 stainless steel round bar offers several distinct advantages, including excellent resistance to intergranular corrosion and superior stability at high temperatures. The addition of niobium in its composition prevents carbide precipitation, ensuring the alloy maintains its strength and corrosion resistance even under thermal stress. This makes it particularly suitable for applications involving frequent temperature fluctuations and high heat, such as in exhaust manifolds, boiler tubes, and chemical processing equipment. Furthermore, its robust mechanical properties and durability enhance its performance in demanding environments. Overall, the 347 stainless steel round bar provides a reliable and durable solution for high-temperature and corrosion-prone applications.

347h stainless steel round bar

The 347H stainless steel round bar offers significant advantages, particularly its enhanced strength and creep resistance at high temperatures due to its higher carbon content. This makes it ideal for demanding applications in the petrochemical, chemical processing, and power generation industries. It also provides excellent resistance to intergranular corrosion, even after prolonged exposure to elevated temperatures, thanks to the addition of niobium which stabilizes the alloy. Its durability and ability to maintain mechanical properties under thermal stress ensure reliable performance in critical high-temperature environments. Overall, the 347H stainless steel round bar is a robust and dependable choice for high-stress, high-temperature applications.

The 317 stainless steel round bar offers several key advantages, including exceptional corrosion resistance, particularly against acidic and chloride environments due to its high molybdenum content. This makes it highly suitable for use in chemical processing and petrochemical industries. It also exhibits superior resistance to pitting and crevice corrosion, ensuring durability in harsh conditions. Additionally, the 317 stainless steel round bar has excellent mechanical properties and high strength, providing reliable performance in demanding applications. Its robustness and durability make it a preferred choice for long-term use in environments where both corrosion resistance and structural integrity are crucial.

317l stainless steel round bar

The 317L stainless steel round bar offers several significant advantages, including exceptional corrosion resistance, particularly in aggressive environments with high chloride and acidic exposure. Its low carbon content minimizes the risk of sensitization during welding, enhancing its suitability for welded applications. Additionally, the alloy provides superior resistance to pitting and crevice corrosion, ensuring long-term durability and reliability. The 317L stainless steel round bar also maintains excellent mechanical properties and strength, making it an ideal choice for demanding applications in chemical processing, petrochemical, marine, and food processing industries. Overall, it combines robust performance with enhanced weldability and corrosion resistance.

2520 stainless steel round bar

The 2520 stainless steel round bar, also known as 310S, boasts several key advantages, including exceptional resistance to oxidation and corrosion at high temperatures. Its high chromium and nickel content ensure excellent performance in severe thermal environments, maintaining structural integrity and mechanical properties. This makes it ideal for demanding applications such as furnace components, heat exchangers, and kiln liners. Additionally, its robustness and durability in fluctuating thermal conditions provide reliable long-term performance, reducing maintenance needs and operational costs. Overall, the 2520 stainless steel round bar offers superior heat resistance, strength, and longevity in high-temperature industrial applications.