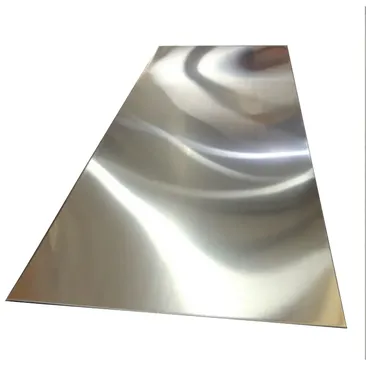

The 304 stainless steel plate offers numerous advantages, including exceptional corrosion resistance, durability, and versatility. Its resistance to corrosion in various environments, such as acidic and alkaline conditions, makes it suitable for a wide range of applications, including food processing, architectural, and chemical industries. Additionally, its ease of fabrication, excellent formability, and attractive appearance further enhance its appeal, making it a preferred choice for both industrial and consumer products where reliability, aesthetics, and longevity are paramount.

The 304H stainless steel plate offers several advantages, notably its elevated temperature strength and enhanced corrosion resistance. Its higher carbon content compared to standard 304 stainless steel improves its mechanical properties, making it ideal for applications requiring resistance to high temperatures and aggressive environments. This makes it suitable for use in pressure vessels, heat exchangers, and boiler components in industries such as chemical processing and power generation, where stability and reliability are paramount.

The 304N stainless steel plate offers several advantages, notably its enhanced strength and corrosion resistance properties due to the addition of nitrogen. This makes it well-suited for applications in demanding environments such as chemical processing, nuclear power plants, and high-pressure vessels. Its improved mechanical properties ensure durability and reliability, making it a preferred choice for critical components where resistance to corrosion, oxidation, and high temperatures is crucial.

The 321 stainless steel plate boasts several advantages, including exceptional high-temperature resistance, superior corrosion resistance, and good mechanical properties. Its ability to withstand prolonged exposure to elevated temperatures makes it ideal for applications in aerospace, chemical processing, and automotive industries where components operate under demanding conditions. Additionally, its resistance to intergranular corrosion enhances its durability, ensuring reliable performance in aggressive environments. Overall, the 321 stainless steel plate offers reliability, longevity, and versatility in critical applications where stability and corrosion resistance are paramount.

The 316 stainless steel plate offers numerous advantages, primarily its exceptional corrosion resistance, particularly in chloride-rich environments. This makes it ideal for a wide range of applications in marine, chemical, and pharmaceutical industries where exposure to harsh conditions is common. Additionally, its high temperature and creep resistance, along with its excellent mechanical properties, ensure durability and reliability in demanding environments. Its versatility and hygienic properties also make it a preferred choice for applications in food processing, medical implants, and architectural structures, where hygiene, aesthetics, and longevity are crucial.

The 316H stainless steel plate offers several advantages, particularly its elevated temperature strength and improved mechanical properties due to its higher carbon content. This makes it well-suited for applications in demanding environments such as chemical processing, petrochemical, and food processing industries. Its enhanced resistance to high temperatures and corrosion ensures durability and reliability, making it a preferred choice for critical components where stability and performance are paramount.

The 316Ti stainless steel plate offers several advantages, notably its superior corrosion resistance and enhanced stability at elevated temperatures. Its titanium addition improves resistance to sensitization and intergranular corrosion, making it ideal for applications in aggressive environments such as chemical processing and marine engineering. The 316Ti plate's durability, reliability, and longevity ensure optimal performance in demanding conditions, making it a preferred choice for critical components where corrosion resistance and temperature stability are essential.

The 347 stainless steel plate offers several advantages, notably its exceptional resistance to intergranular corrosion and high-temperature environments. Its stabilization with columbium enhances its durability and reliability in aggressive chemical environments, making it suitable for applications in industries such as chemical processing, petrochemical, and aerospace. The 347 stainless steel plate's ability to withstand elevated temperatures and resist sensitization ensures optimal performance in critical components such as heat exchangers, furnace components, and exhaust systems, making it a preferred choice for demanding applications where corrosion resistance and temperature stability are paramount.

The 347H stainless steel plate offers several advantages, notably its elevated temperature strength and enhanced resistance to corrosion. With a higher carbon content compared to standard 347 stainless steel, it exhibits superior performance in high-temperature environments, making it ideal for applications in industries such as chemical processing, petrochemical, and power generation. Its ability to withstand aggressive chemical environments and maintain stability ensures reliability and longevity in critical components such as heat exchangers and furnace components, making it a preferred choice for demanding applications where strength and corrosion resistance are essential.

The 317 stainless steel plate offers several advantages, primarily its exceptional corrosion resistance and high temperature stability. With a higher molybdenum content, it exhibits superior resistance to chloride-induced corrosion, making it ideal for use in aggressive environments such as chemical processing, pulp and paper, and marine engineering. Its ability to withstand elevated temperatures and harsh conditions ensures reliability and longevity in critical components such as chemical storage tanks, flue gas desulfurization systems, and seawater handling equipment, making it a preferred choice for demanding applications where corrosion resistance and temperature stability are paramount.