The 440A stainless steel plate boasts several advantages, notably its high hardness, moderate corrosion resistance, and excellent edge retention. Its high carbon content enhances its hardness, making it ideal for applications where maintaining sharpness and withstanding wear are critical. Additionally, its affordability and ease of fabrication contribute to its versatility in various industrial and commercial uses. Overall, the 440A stainless steel plate provides reliable performance and durability in demanding conditions where hardness and corrosion resistance are essential.

The 440C stainless steel plate offers several advantages, notably its exceptional hardness, wear resistance, and corrosion resistance. With its high carbon content, it maintains sharpness and withstands heavy loads, making it ideal for applications such as cutlery manufacturing and aerospace. Its superior edge retention ensures durability and precision, contributing to its reliability in demanding conditions. Overall, the 440C stainless steel plate provides consistent performance where hardness, wear resistance, and corrosion resistance are crucial.

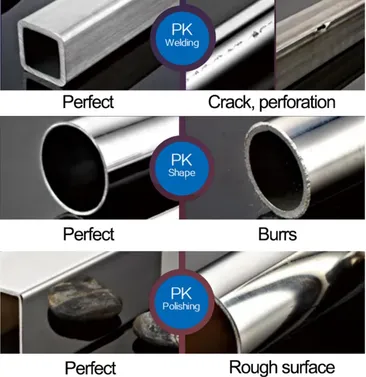

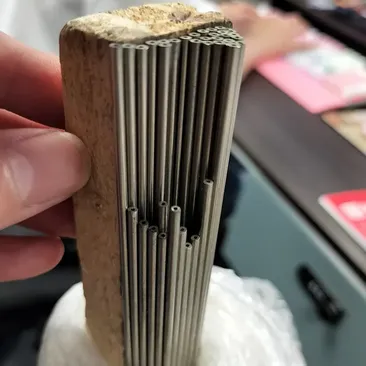

The 202 stainless steel pipe offers several advantages, including good corrosion resistance, moderate strength, and cost-effectiveness. Its affordability makes it an attractive option for budget-conscious projects without compromising on performance. It performs well in mild corrosive environments and is versatile, making it suitable for a wide range of applications such as structural components, automotive exhaust systems, and kitchen utensils. Overall, the 202 stainless steel pipe provides reliable durability and performance at a lower cost compared to other stainless steel grades.

The 410 stainless steel pipe offers several advantages, including high strength, good wear resistance, and moderate corrosion resistance. Its ability to withstand high temperatures and abrasive conditions makes it ideal for demanding applications in industries such as oil and gas, petrochemical, and power generation. Additionally, its durability and mechanical strength make it suitable for components like pump shafts, valves, and fasteners. Overall, the 410 stainless steel pipe provides reliable performance and longevity in harsh environments where both strength and moderate corrosion resistance are crucial.

The 440 stainless steel pipe offers several advantages, including exceptional hardness, excellent wear resistance, and good corrosion resistance. Its high carbon content contributes to its superior hardness and edge retention, making it ideal for demanding applications in industries such as aerospace, medical equipment, and cutlery manufacturing. Additionally, it performs well in high-stress environments, ensuring durability and reliability in critical components like surgical instruments and valve parts. Overall, the 440 stainless steel pipe provides outstanding performance and longevity in applications where both hardness and corrosion resistance are essential.

The 630 stainless steel pipe, also known as 17-4 PH stainless steel, offers several advantages, including high strength, excellent corrosion resistance, and good mechanical properties. Its precipitation-hardening capability allows it to achieve high hardness and strength, making it ideal for demanding applications in aerospace, chemical processing, and petrochemical industries. Additionally, it maintains its properties across a wide range of temperatures, ensuring durability and reliability in harsh environments. Overall, the 630 stainless steel pipe provides exceptional performance in applications where strength, corrosion resistance, and temperature stability are essential.

The 409 stainless steel pipe offers several advantages, including good corrosion resistance, high-temperature tolerance, and cost-effectiveness. Its ability to withstand the high temperatures and corrosive environments typical of automotive exhaust systems makes it ideal for components like exhaust pipes, catalytic converters, and mufflers. Additionally, its affordability makes it an attractive option for manufacturers, ensuring reliable performance without significantly increasing costs. Overall, the 409 stainless steel pipe provides a balanced combination of durability, heat resistance, and economic value, making it a preferred choice in various industrial applications.

The 409L stainless steel pipe offers several advantages, including good corrosion resistance, high-temperature tolerance, and excellent weldability due to its low carbon content. These properties make it ideal for automotive exhaust systems, such as catalytic converters and mufflers, where it can withstand high temperatures and corrosive exhaust gases. Additionally, its formability and durability make it suitable for industrial applications like heat exchangers and agricultural equipment. Overall, the 409L stainless steel pipe provides a reliable, cost-effective solution for applications requiring robust performance and ease of fabrication.

The 301 stainless steel pipe offers several advantages, including high strength, excellent corrosion resistance, and good formability. Its high tensile strength allows it to withstand mechanical stress, making it ideal for structural components and springs. Additionally, its excellent corrosion resistance ensures durability in corrosive environments, while its good formability and weldability make it suitable for manufacturing complex shapes and assemblies. Overall, the 301 stainless steel pipe provides reliable performance and versatility in demanding industrial and commercial applications.

The 302 stainless steel pipe offers several advantages, including excellent corrosion resistance, high tensile strength, and good formability. Its superior resistance to corrosion makes it ideal for use in harsh environments, such as chemical processing and marine applications. The high tensile strength ensures durability and reliability in demanding conditions, while its good formability allows for easy fabrication into complex shapes and assemblies. Overall, the 302 stainless steel pipe provides a robust and versatile solution for a wide range of industrial and commercial applications.