Stainless steel round bar is a common type of steel, which is widely used in industrial production, machining, construction and other fields.

H-beam is a kind of Economic section steel, which sectional area distribution is more optimized, the ratio of strength to weight is more reasonable, Mechanical properties of section is more better.It is developed from the I-section steel optimization of a better section mechanical properties of the economic section steel, because its section is same as the English letter "H" ,so be named as H-Beam. Because the various part of H-beam is arranged at right angles, H-beam has the advantages of strong bending resistance, simple construction, cost saving and light structural weight in all directions, so it has been widely used.

Stainless H beam is widely used in beams and columns of industrial and civil steel structures. Steel structure load-bearing supports for industrial structures. Ship and machinery manufacturing frame structure. Steel piles and supporting structures of underground works.

With the rise of new economic building materials, galvanized H-shaped steel is widely used, especially in steel structure buildings, supports, and bridges. In short, it is integrated with many aspects of daily life.

Hot rolled stainless steel light channel steel (YB164-63) Hot rolled light channel steel is a kind of steel with wide legs and thin walls, which has better economic effect than ordinary hot rolled channel steel. Main use: for building and steel structure.

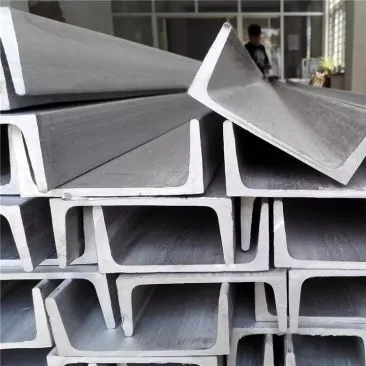

Uchannel(U-STEEL) is a long stripe of steel with a fluted section , construction and mechanical use of carbon structural steel, is a profile steel with complex section , its section shape is groove shape. U-Steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing., u-steel is often used together with I steel.

Galvanized channel steel is an effective way of metal corrosion prevention, which is mainly used on metal structures and facilities in various industries.

1.Advantage: Competitive price and quality from our own factory.2.Certification : Approved by ISO9001, CE, SGS every year. 3.We promise that all steel sold will have a 2-year warranty period and will be responsible for every batch of goods you buy!

1.Advantage: Competitive price and quality from our own factory.2.Certification : Approved by ISO9001, CE, SGS every year. 3.We promise that all steel sold will have a 2-year warranty period and will be responsible for every batch of goods you buy!

1.Advantage: Competitive price and quality from our own factory.2.Certification : Approved by ISO9001, CE, SGS every year. 3.We promise that all steel sold will have a 2-year warranty period and will be responsible for every batch of goods you buy!