Characteristics:Weather proof; heating insulation; fireproof; anti-rust; sound insulation; long life span: more than 20 years.Corrosion Resistance: the aluzinc coating surface protects the base steel not only by providing barrier to corrosion elements, butalso by the sacrificial nature of the coating.

Characteristics:Weather proof; heating insulation; fireproof; anti-rust; sound insulation; long life span: more than 20 years.Corrosion Resistance: the aluzinc coating surface protects the base steel not only by providing barrier to corrosion elements, butalso by the sacrificial nature of the coating.

Characteristics:Weather proof; heating insulation; fireproof; anti-rust; sound insulation; long life span: more than 20 years.Corrosion Resistance: the aluzinc coating surface protects the base steel not only by providing barrier to corrosion elements, butalso by the sacrificial nature of the coating.

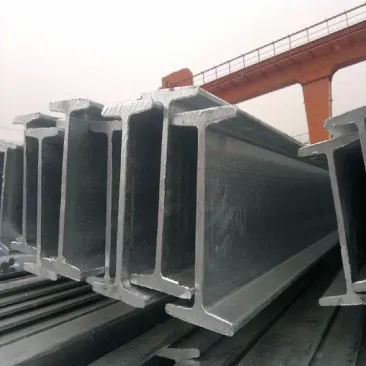

I-beam, also known as steel beam (English name universal Beam), is a long steel with the section of the I-shaped. I-section steel is divided into hot rolIed I-beam and lightweight I-beam

Stainless steel I-beam is a long steel bar with a grooved section. It can be used to form various stress components according to the different needs of the structure, and can also be used as a connector between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, hoisting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.Stainless steel I-beam is a carbon structural steel used for construction. It is a simple section steel, mainly used for metal components and plant frames. Good weldability, plastic deformation performance and mechanical strength are required in use. The raw steel billet of stainless steel I-beam is low carbon square steel billet, and the finished stainless steel I-beam is delivered in hot rolling forming, normalizing or hot rolling state.

The characteristics of galvanized I steel: 1. Strong corrosion resistance: the thickness of hot-dip galvanized layer can reach more than 300 m; 2. Good plasticity and toughness: no deformation in cold bending; 3. High strength: it can be used as the load-bearing framework of ceiling enclosure plate. 4. Good fire resistance: high melting point (1000 ° C), strong fire resistance; 5. Long service life: ≥ 100 years. 6. Flexible and fast installation: short construction period. 7. The color is bright and durable, without surface decoration

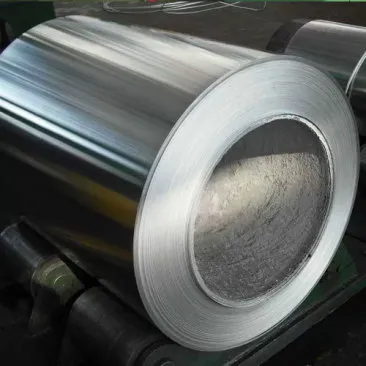

Wire rod is a rolled steel product (alloy or non-alloy), manufactured from a semi-finished steel with a rectangular, rounded,hexagonal or squared shape. Especially, fine cross-sections are reached by sequent cold drawing. Wire rod is wrapped around into the coils and also carried in this form.Steel wire rods can be used for a wide range of products depending on how it is shaped and treated. The main usage is wire mesh, nails springs, reinforcement wire, barbed wire, wire ropes , welded wire mesh.

JIS G3536:1×7-12.7mm/15.2mm;UNE 36094:1×7-9.3mm/13.0mm/15.2mm;KS D:1×7-9.5mm/11.1.0mm/12.7mm/15.2mm;AS/NZS4672:9.5mm(7 wire)/12.7nn/15.2mm;

Advantage: Competitive price and quality from our own factoryCertification : Approved by ISO9001, CE, SGS every year

2024 aluminum plate is a typical duralumin in al-cop-magnesium system with reasonable composition and good comprehensive properties.

The alloy is produced in many countries and is the most widely used duralumin.

The characteristics of the alloy are: high strength, a certain degree of heat resistance, can be used for working parts below 150℃.