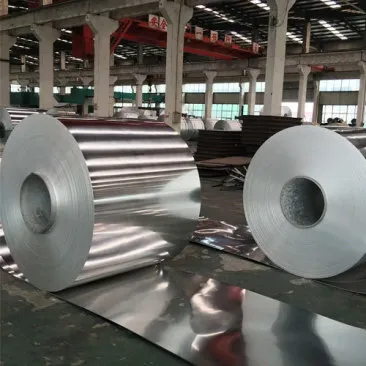

6082 is a heat-treatable alloy with good formability, weldability, machinability and corrosion resistance.

It also has moderate strength and can maintain good operability after annealing.

It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

Thickness: 0.15-600mm

Port of Destination: Any port you like

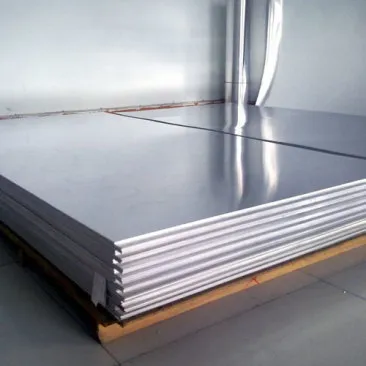

Aluminium Sheets with high strength is mainly used make Fire Engine Side Panel and Dump Truck Floor in industry.

Because of its good energy absorption ability in collision experiment, engine mount, side impact beam, engine splash shield, ABS, airbag part, etc.

Aluminium Sheets with high strength is mainly used make Fire Engine Side Panel and Dump Truck Floor in industry.

Because of its good energy absorption ability in collision experiment, engine mount, side impact beam, engine splash shield, ABS, airbag part, etc.

Thickness: 0.15-150mm

Port of Destination: Any port you like

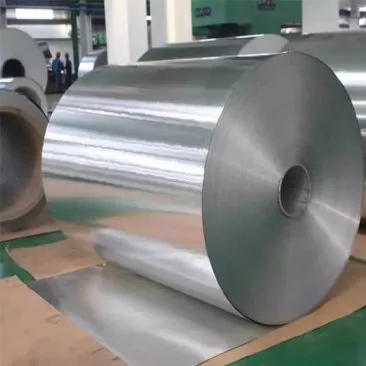

Aluminium Sheets with high strength is mainly used make Fire Engine Side Panel and Dump Truck Floor in industry.

Because of its good energy absorption ability in collision experiment, engine mount, side impact beam, engine splash shield, ABS, airbag part, etc.

Thickness: 0.15-150mm

Port of Destination: Any port you like

Aluminium Sheets with high strength is mainly used make Fire Engine Side Panel and Dump Truck Floor in industry.

Because of its good energy absorption ability in collision experiment, engine mount, side impact beam, engine splash shield, ABS, airbag part, etc.

5083 belongs to Al-Mg-Si alloy, which is widely used, especially in the construction industry.

It is the most promising alloy. Good corrosion resistance, good weldability, good cold processing, and has moderate strength.

The main alloy element of 5083 is magnesium, which has good forming performance, corrosion resistance, weldability and medium strength.

Al metal alloy: 1000, 2000, 3000, 4000, 5000, 6000, 7000, 8000 series etc

Alu temper: O - H112, T3 - T8, T351 - T851 etc

Thickness: 0.3mm - 6mm

Width: 900mm - 1600mm

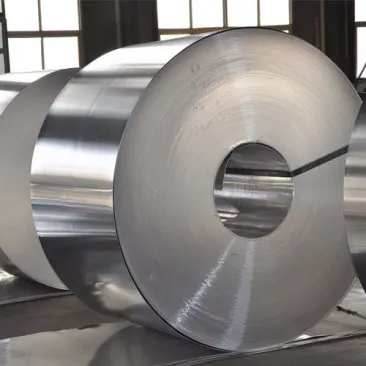

6082-T6 aluminum, the main alloying elements in the alloy are magnesium and silicon, with excellent processing performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, coating, excellent anodic oxidation effect, is a typical extrusion alloy.

Widely used in building profiles, irrigation pipes, pipes, bars and profiles for vehicles, platforms, furniture, elevators and fences.

The electrical and thermal conductivity of copper is second only to silver, and is widely used to make conductive and thermally conductive equipment. Copper has good corrosion resistance in the atmosphere, seawater and certain non-oxidizing acids, alkalis, salt solutions and a variety of organic acids (acetic acid, citric acid), and is used in the chemical industry. In addition, copper has good weldability and can be made into various semi-finished and finished products by cold and thermoplastic processing.

The electrical and thermal conductivity of copper is second only to silver, and is widely used to make conductive and thermally conductive equipment. Copper has good corrosion resistance in the atmosphere, seawater and certain non-oxidizing acids, alkalis, salt solutions and a variety of organic acids (acetic acid, citric acid), and is used in the chemical industry. In addition, copper has good weldability and can be made into various semi-finished and finished products by cold and thermoplastic processing.