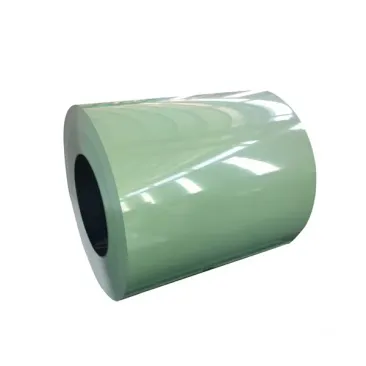

Galvanized sheet G550 belongs to high-strength series galvanized sheet, with high requirements for tensile strength and yield strength. Its minimum yield strength is 560Mpa, minimum tensile strength is 650Mpa, and zinc layer thickness is 275g/m2. It has strong corrosion resistance and is mainly used for building structures with high strength requirements, such as Z-shaped steel, C-shaped steel, floor bearing plate, etc.

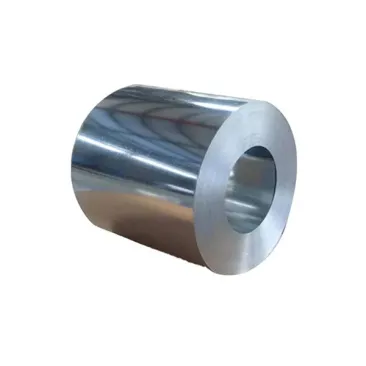

Stainless steel is an alloy of Iron with a minimum of 10.5% Chromium. Chromium produces a thin layer of oxide on the surface of the steel known as the passive layer. This prevents any further corrosion of the surface. Increasing the amount of Chromium gives an increased resistance to corrosion.

Uchannel(U-STEEL) is a long stripe of steel with a fluted section , construction and mechanical use of carbon structural steel, is a profile steel with complex section , its section shape is groove shape. U-Steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing., u-steel is often used together with I steel.

01. SMOOTHNESSNo composite indentation, no residual stress, no deformation after shearing.

Stainless steel coils are imported and domestic products, divided into hot-rolled and cold-rolled. According to the needs of different users, we can also order a variety of special-shaped steel materials.In order to ensure that the yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery.

2036 aluminum this is an early application of a kind of hard aluminum, commonly known as standard hard aluminum, with moderate strength, annealing, quenching and hot state plasticity is good, heat treatment can be strengthened, quenching and natural aging state in use, spot welding weldability is good.

2036 aluminum alloy features: high strength, a certain heat resistance, can be used for working parts below 150℃. The strength of 2036 alloy is higher than that of 7075 alloy.

1070 aluminum bar divided into several names, 1070 pure aluminum bar, 1070 aluminum bar, A1070 aluminum bar, O state 1070 aluminum bar, H state 1070 aluminum bar.

The so-called O state,O state 1070 aluminum rod meaning again in O state belongs to pure aluminum inside the meaning of aluminum content O state 1070 pure aluminum aluminum purity can reach 99.60℃ has the effect of tensile, electric/thermal conductivity is very fast, hot rolling performance.

1100 aluminum alloy is 99.0% ordinary industrial pure aluminum.

Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance; After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained.

5052 aluminum is Al-Mg alloy aluminum, magnesium is the main alloy element in

5052 alloy aluminum, is the most widely used one kind of rustproof aluminum, this alloy has high strength, especially the fatigue strength: High plasticity and corrosion resistance, heat treatment can not be strengthened, in the semi-cold hardening plasticity is good, cold hardening plasticity is low, good corrosion resistance, good weldability, poor cutting performance, polishing.

2024 aluminum alloy, the main alloying elements are copper and magnesium.

Applications where high strength but low weight ratio is required, and good fatigue strength.

Not weldable, general processing performance.

Because of poor corrosion resistance, aluminum-zinc splints are often used as protection, which results in reduced fatigue strength.