Copper tubes are also known as copper tubes. A type of non-ferrous metal pipe, which is a pressed and drawn seamless tube. Copper pipe has the characteristics of good electrical conductivity, thermal conductivity, conductive accessories of electronic products and the main material of heat dissipation accessories, and has become the first choice for modern contractors to install water pipes, heating and cooling pipes in all residential commercial houses.

Copper tubes are also known as copper tubes. A type of non-ferrous metal pipe, which is a pressed and drawn seamless tube. Copper pipe has the characteristics of good electrical conductivity, thermal conductivity, conductive accessories of electronic products and the main material of heat dissipation accessories, and has become the first choice for modern contractors to install water pipes, heating and cooling pipes in all residential commercial houses.

In life, copper wire is used as a wire. Very good electrical conductivity, a large number of used in the manufacture of wires, cables, brushes, etc.; Good thermal conductivity, commonly used to manufacture magnetic instruments and meters that must prevent magnetic interference, such as compasses, aviation instruments, etc.; Excellent plasticity, easy to hot press and cold pressure processing, can be made into tubes, rods, wires, strips, strips, strips, plates, foils and other copper. Pure copper products have two types: smelted products and processed products.

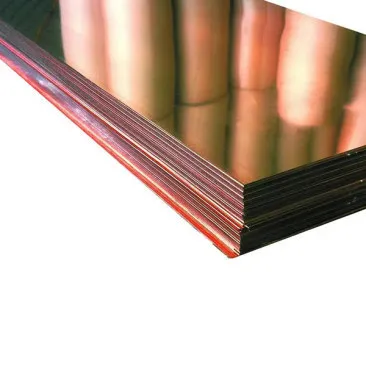

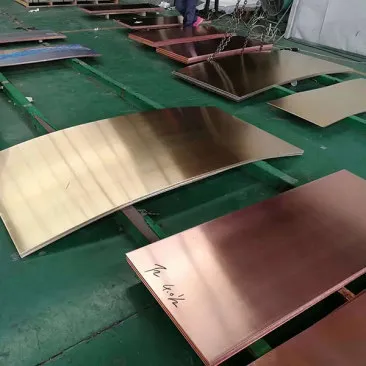

Copper plate is a highly stable, low-maintenance roofing and curtain wall material that is environmentally friendly, safe to use, easy to process and extremely resistant to corrosion.Aluminum bronze, tin bronze, silicon bronze, beryllium bronze, copper, brass, cupronickel, tungsten copper, red copper, oxygen-free copper.

Copper plate is a highly stable, low-maintenance roofing and curtain wall material that is environmentally friendly, safe to use, easy to process and extremely resistant to corrosion.Aluminum bronze, tin bronze, silicon bronze, beryllium bronze, copper, brass, cupronickel, tungsten copper, red copper, oxygen-free copper.

Copper plate is a highly stable, low-maintenance roofing and curtain wall material that is environmentally friendly, safe to use, easy to process and extremely resistant to corrosion.Aluminum bronze, tin bronze, silicon bronze, beryllium bronze, copper, brass, cupronickel, tungsten copper, red copper, oxygen-free copper.

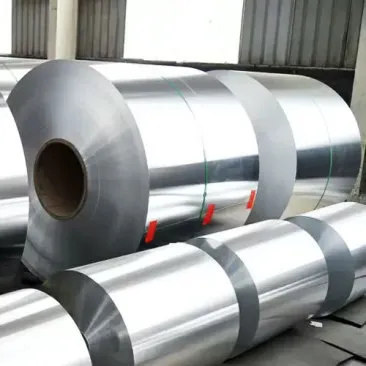

2036 aluminum this is an early application of a kind of hard aluminum, commonly known as standard hard aluminum, with moderate strength, annealing, quenching and hot state plasticity is good, heat treatment can be strengthened, quenching and natural aging state in use, spot welding weldability is good.

2036 aluminum alloy features: high strength, a certain heat resistance, can be used for working parts below 150℃.

The strength of 2036 alloy is higher than that of 7075 alloy.

1100 aluminum alloy is 99.0% ordinary industrial pure aluminum.

Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance;

After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained.

1070 aluminum has high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity, but low strength, not through heat treatment to strengthen, cutting is not good, can accept contact welding, gas welding.

Make use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil gaskets and capacitors, electronic tube isolation net, wire, cable protection sleeve, net, wire core and aircraft ventilation system parts and decorative parts.

1100 aluminum alloy is 99.0% ordinary industrial pure aluminum.

Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance;

After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained.