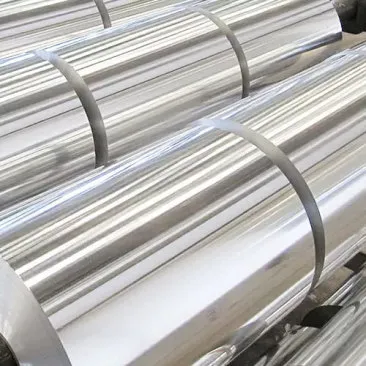

The main alloying elements in 6061 alloy are magnesium and silicon, which have moderate strength, good corrosion resistance, weldability and good oxidation effect.

Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.

6082 is a heat-treatable alloy with good formability, weldability, machinability and corrosion resistance.

It also has moderate strength and can maintain good operability after annealing.

It is mainly used in mechanical structure, including bars, plates, pipes and profiles.

7075-T6 aluminum alloy hardness is 150HB, belongs to the high hardness aluminum alloy.

7075T6 aluminum alloy is precision machined aluminum in the United States, one of the most commercially available alloys.

The main alloying element of 7075 series is zinc, which has strong strength, good mechanical properties and anode reaction.

6063 aluminum alloy material.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

7075 aluminum alloy is a cold - treated forging alloy, high strength, far better than mild steel.

7075 is one of the strongest alloys commercially available.

Under heat treatment, can achieve very high strength characteristics.

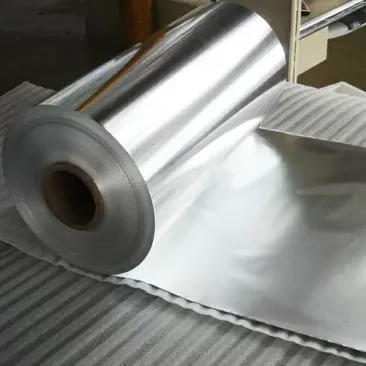

5083 belongs to Al-Mg-Si alloy, which is widely used, especially in the construction industry.

It is the most promising alloy.

Good corrosion resistance, good weldability, good cold processing, and has moderate strength.

The main alloy element of 5083 is magnesium, which has good forming performance, corrosion resistance, weldability and medium strength.

1. Power industry -- fan blades, burner pipelines, feeder and hopper lining, crusher parts, coal grinder parts, ash pipes, airhandling systems and conveyors;2. Have spentIron and steel industry - hopper lining, grille, feeder and base, dump truck, hopper, pipe, pump shell, crusherparts, slag trough, various chassis, vibrating screen;

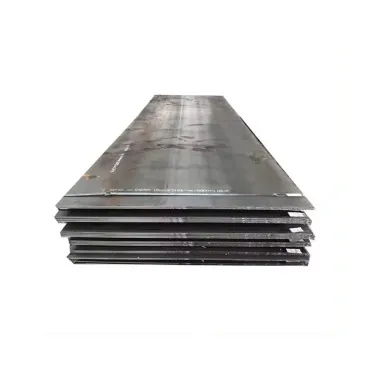

Steel coils are classified according to their professional uses, including oil drum plates, bulletproof plates, shipbuilding plates, automobile plates, construction plates, machining plates, etc.Specializing in the production and sales of carbon steel coils, factory direct sales, product grades and specifications are complete, and can certainly meet your various needs, welcome to consult

1. For pipelines. Water, gas pipes, steam pipes, and oil and gas trunk lines. 2. Tubes for thermal equipment. Superheating pipes, high temperature and high-pressure boiler pipes for locomotive boilers. 3. For the machinery industry. Aviation structural tubes, automobile axle tubes, tractor structural tubes, etc.

Round steel belongs to carbon structural steel for construction and machinery, while square steel belongs to carbon structuralsteel for machinery. Both of them are simple section steel, and their section shapes are respectively round and square. Low carbon is mainly used fordrawing wire, forging rivets, bolts, nuts and other metal products of raw materials. Medium carbon round steel and square steelare generally used to make mechanical structural parts.