Galvanized sheet G550 belongs to high-strength series galvanized sheet, with high requirements for tensile strength and yield strength. Its minimum yield strength is 560Mpa, minimum tensile strength is 650Mpa, and zinc layer thickness is 275g/m2. It has strong corrosion resistance and is mainly used for building structures with high strength requirements, such as Z-shaped steel, C-shaped steel, floor bearing plate, etc.

Color Coated 304 Stainless Steel

Decoration field304 stainless steel can be used in decoration field. 304 stainless steel has been widely used in the decoration industry due to its high tensile strength, good internal wall finish and excellent wear resistance. Just like our common stainless steel stair guardrails, handrails, stainless steel anti-theft windows, stainless steel doors, stainless steel tables and chairs, they are all made of 304 stainless steel decorative tubes. In life, the bathroom is wet and the kitchen is full of lampblack, so 304 stainless steel can be used in these two places.

316L stainless steel is commonly used in pulp and paper making equipment, heat exchanger, dyeing equipment, film processing equipment, pipes, materials used for the exterior of buildings in coastal areas, as well as watch chains and case of advanced watches.

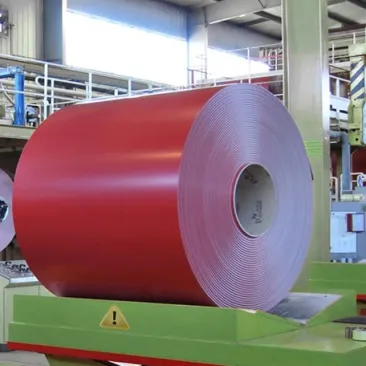

Stainless steel strip is an extension of ultra-thin stainless steel plate, and is also a kind of steel plate used in industry. However, unlike ordinary steel plates, stainless steel strip has a longer shape, and its scope of use is also different from ordinary steel plates. At present, there are many varieties of stainless steel strips, and there are also many different production specifications. Different stainless steel strips use different categories. Cold rolled strip is a specially treated stainless steel strip product. It is another industrial steel strip product, which is made of stainless steel strip as the basic material and is processed by cold rolling mill at room temperature. The rolled strip has excellent characteristics such as smooth surface, flatness, high dimensional accuracy and good mechanical functions, and is often processed into rolls and coated steel plates. Cold rolled strip is widely used in tractor, car and other industrial manufacturing. Hot rolled strip is another kind of stainless steel strip, which has low hardness, easy processing, good ductility and other excellent characteristics, so it is often used as a thin plate.

01. SMOOTHNESSNo composite indentation, no residual stress, no deformation after shearing.

01. SMOOTHNESSNo composite indentation, no residual stress, no deformation after shearing.

The angle steel is mainly used to make frame structures, such as high-voltage transmission towers, frames on both sides of the main beam of steel structure bridges, columns and booms of tower cranes on construction sites, columns and beams of workshops, etc., small places such as flower pot shaped shelves at the festival roadside, and shelves with air-conditioning and solar energy hung under windows. Angle steel is also widely used in building structures and engineering construction, such as house beams, power transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.

Use of galvanized angle steel: widely used in power tower, communication tower, curtain wall materials, shelf construction, railway, highway protection, street lamp pole, marine components, building steel structure components, substation ancillary facilities, light industry, etc.

1 Stainless steel angle steel is widely used in the construction layout, as well as in various engineering layouts, such as the construction of beams, and has a significant effect in the construction of engineering equipment.2. When used, stainless steel angle steel has comparative weldability, strong plasticity and deformation, and also has certain mechanical strength.3. The corrosion resistance of stainless steel angle steel is relatively high, and it has good corrosion resistance in the production process of pulp and paper. Moreover, stainless steel is also resistant to the corrosion of ocean and corrosive industrial atmosphere.4. Stainless steel angle steel can be used as equipment for dry pulp and paper making, heat exchanger, dyeing equipment, film processing equipment, pipes, and materials for the exterior of buildings in coastal areas.5. Precipitation hardening stainless steel angle steel is a steel that can precipitate carbides in the steel by means of heat treatment, so as to improve the strength.6. Martensitic stainless steel angle steel is a kind of steel whose properties can be adjusted by means of heat treatment. Its strength and hardness are high and it is very useful in technology and mechanics.

Characteristics:Weather proof; heating insulation; fireproof; anti-rust; sound insulation; long life span: more than 20 years.Corrosion Resistance: the aluzinc coating surface protects the base steel not only by providing barrier to corrosion elements, butalso by the sacrificial nature of the coating.